Chrome Restoration

You cannot have a beautifully restored car without having placed the same degree of attention to the body moulds and chrome work. Quite often I hear stories about bright work components that are left aside during the restoration and not even thought about until the car is painted. I imagine that sometimes the reason for this is the bright work might be in reasonable condition and therefore the decision was made to not restore the accessories and maybe just clean it up before reassembling. That may have been a valid thought when dismantling the car, however, the beautiful new body and paintwork along with the efforts that have gone in at that point, almost certainly validates the chrome work being restored as well.

Some of the problems that arise if the bright work is left until after painting would be;

- Trial fitting and repairing moulds on a painted car takes greater care as the paintwork is at high risk of accidental damage.

- Cast alloys like light housings cannot be just hit with a hammer and bent into shape to fit the body, the painted body work may need to be modified.

- Capsulated nuts and threads for mounting bright work maybe damaged and metal work including welding might be needed to rectify the problem area to be repainted.

- Bright work not having enough clearance around door frames will chip the new paint away.

- Too much paint applied to areas such as drip rails on the sides of roof turrets is too common and the gutter mouldings simply won't fit.

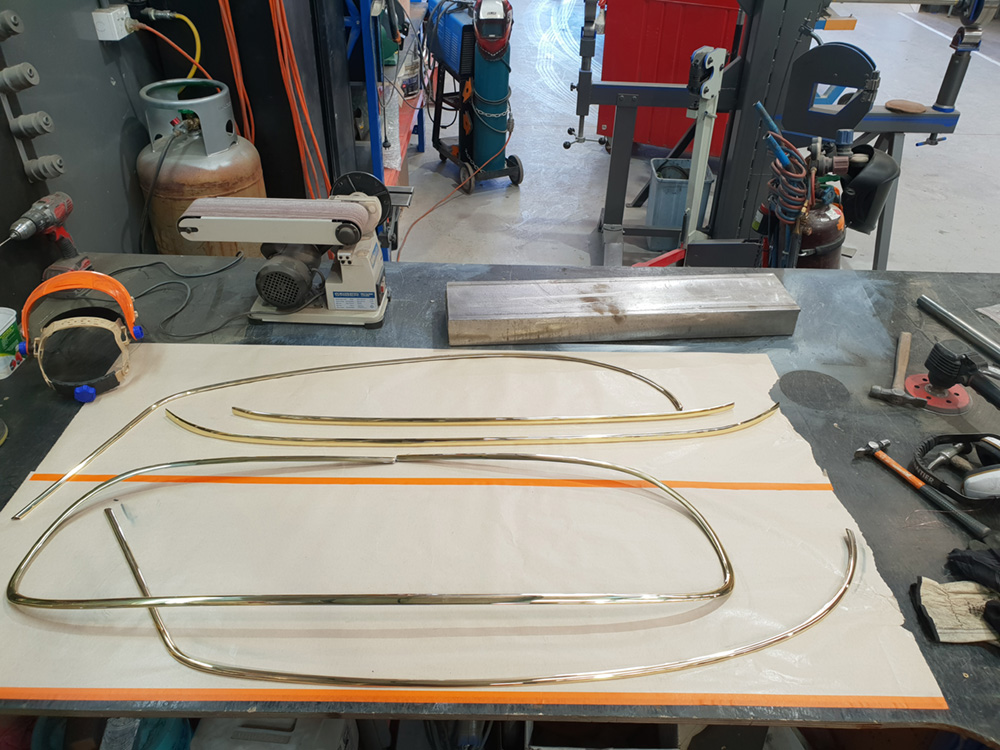

The best time to do all the bright work for the vehicle is during the metal work stage and when the bodywork is completed the bright work can be finalised too. The bright work can often show metal work deformities to the body shell that need to be corrected prior to paint work. There is obviously no risk of damaging paint at this point in time and if the bodywork requires repair or modification then this is the dedicated time in the restoration process to get it right.

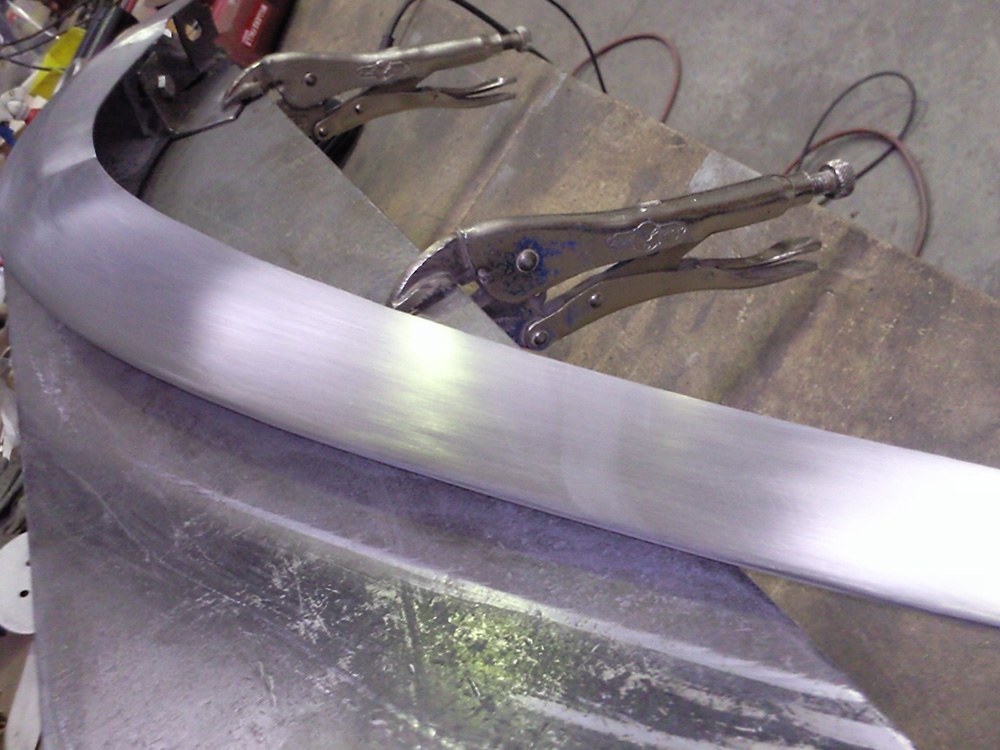

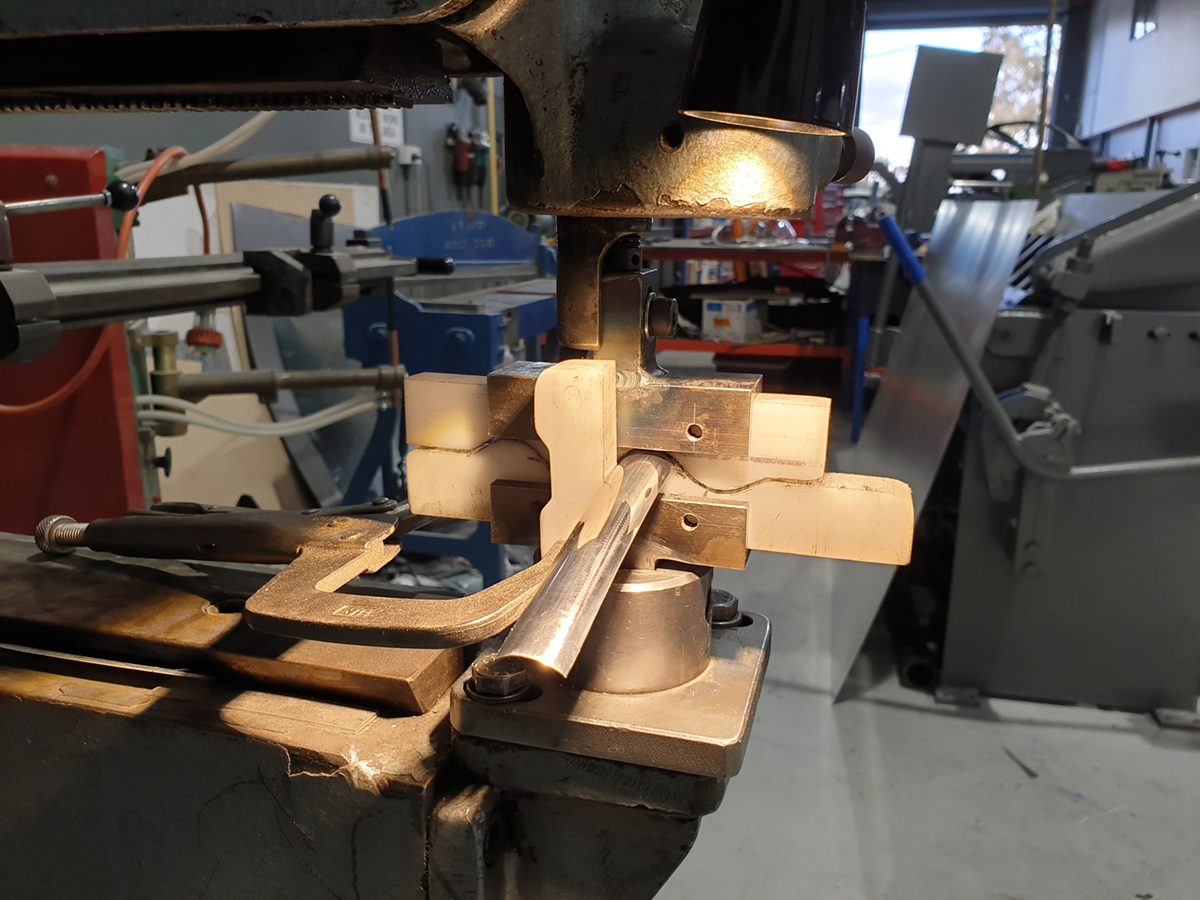

During the process of repairing the individual bright work pieces, each part may require hammering, chasing, shrinking and stretching. The tools used are often very light weighted and commonly handmade bits of metal or nylon of all different shapes and sizes that are accumulated over the years. Brass, steel, aluminium and stainless steel sheet is often very thin and usually only half the thickness of bodywork steel or aluminium. If body moulds are overstretched from being worked too much, they can crack or go out of shape and be a lot more work to get them right again. Great care must be taken so that they look better than new and fit the vehicles contours perfectly.

At Greg Newton Restorations we restore all bright work and metal polishing on our classic car restorations and accident repairs, only sending the components out to have the chemical coating stages applied.

The person painting the car is also required to see all of the chrome work fitting the vehicle so that they know to not change the body contour lines in those areas with polyesters and for the added assurance that the paint is kept to a specific material thickness in certain areas of the body so that the mouldings can still fit after it painted. Once the car is in a primer stage the bright work would then have one more trial fitment before final polishing and chemical processing, readying each component for final assembly after the paintwork is finished.